Search This Supplers Products:Filter mediumMetal fiber feltSintered wire meshSintered filterMesh filterPleated filters

What is the working principle of the air filter?

publisherKim Fu

time2018/08/23

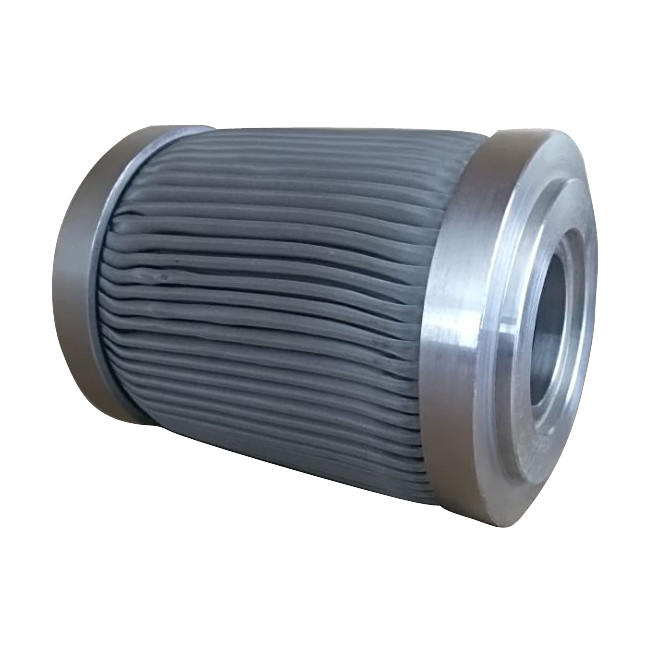

The oil and gas separation filter is a key component that determines the quality of the compressed air discharged from the screw compressor. The correct installation and good maintenance ensure the quality of the compressed air and the life of the filter.

The air compressed from the head of the screw compressor mains is filled with oil droplets of different sizes. The large oil droplets are easily separated by the oil and gas separation tank, while the small oil droplets (suspended) must pass through the micron-sized glass fiber of the oil separation filter. The filter material is filtered. The correct choice of glass fiber diameter and thickness is an important factor to ensure the filtration effect.

After the oil mist is intercepted, diffused and polymerized by the filter material, the small oil droplets are quickly polymerized into large oil droplets, which pass through the filter layer under the action of aerodynamic force and gravity, and settle at the bottom of the filter element. These oils are returned to the lubrication system through the inlet of the return line at the bottom of the filter element, allowing the compressor to discharge relatively pure, high-quality compressed air.

By understanding the working principle of the air compressor filter, the entire filtration process can be clearly understood, and some structures of the filter content can be mastered to enhance our operation and maintenance knowledge.