Search This Supplers Products:Filter mediumMetal fiber feltSintered wire meshSintered filterMesh filterPleated filters

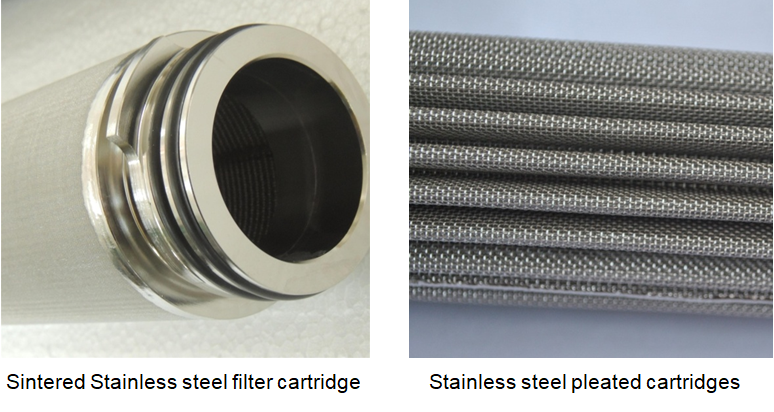

How To Distinguish Stainless Steel sintered filter and Stainless Steel Pleated filter?

Stainlesssteel pleated cartridges are offered in SS 304, SS 316, & SS 316 Lmaterials. These elements can be in pleated configuration to increasefiltration area. Normally all stainless steel pleated filters are supportedwith coarser filter media to ensure no direct damages to main filtering mediaunder process upsets. A bubble point test can be done to certify that noopening larger than the specified pore size exist in product joints or seams.No media migration occurs due to stainless steel material. These elements canbe back washed & reused.

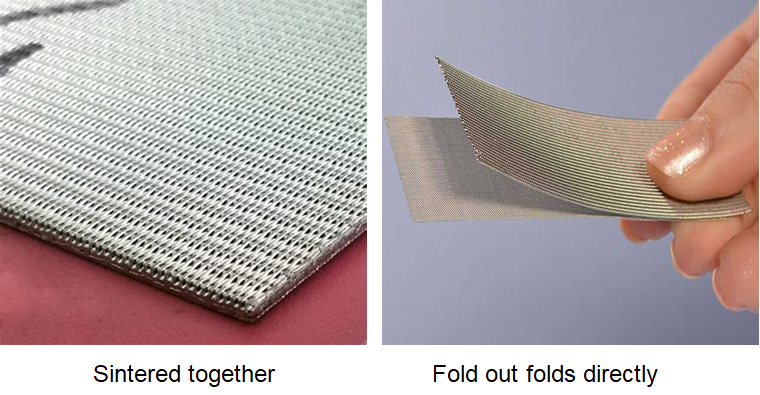

Sintered Stainless steel filter cartridge, is made of stainless steel woven wire mesh, or stainless steel fiber felt. It is constructed by using multi-layered wire mesh overlapped and then sintered together in vacuum furnace, rolled into a cylinder shape with two ends welded together. Rolling seam welding process is added for roundness and flatness of entire structure. Its interlaced mesh forms a rigid structure which overcomes the disadvantages of ordinary wire mesh, such as low strength, unstable hole shapes.

3. Fromthe feature, the stainless steel pleated filter hasa pleated surface so it has a larger filter area but is not easy to clean,whereas sintered stainless steel filter is the opposite.